Under the background of "double carbon", the photovoltaic industry, which converts solar energy into electric energy, is developing rapidly, and monocrystalline silicon solar cells are the main force among them, and their share in the photovoltaic market has risen to more than 95%.

The reason why it is so hot is because monocrystalline silicon has too many advantages. First, silicon is the semiconductor element with the highest content on the earth, and there is no shortage of materials; direct reference.

Nothing is perfect, however, and monocrystalline silicon solar cells have a serious flaw. It is very "fragile". In terms of mechanics, giving it a slight bending stress or vibration during transportation may cause it to shatter directly. This also makes the application scenarios of monocrystalline silicon solar cells very limited.

The scientific research team from the Shanghai Institute of Microsystem and Information Technology of the Chinese Academy of Sciences (hereinafter referred to as the Shanghai Institute of Microsystems) successfully developed a flexible monocrystalline silicon solar cell, achieving a milestone leap. At 23:00 on May 24, this research paper was published online in Nature and was selected as the cover of the current issue. This is also the first long research paper on pure monocrystalline silicon solar cells published in "Nature" since the invention of monocrystalline silicon solar cells 69 years ago.

The research paper was published online in Nature and was selected as the cover of the current issue.

From "V" to "U", realize the transformation of mechanical properties

It is the ideal of many people in the industry to make monocrystalline silicon solar cells flexible and stick them wherever they need to be.

Liu Wenzhu, the first author of the paper and an associate researcher at the Shanghai Institute of Microsystems, considered this issue when he was a student. But what really stimulated his confidence to do this is because in many academic conferences, he can always hear a voice: "Our thin-film batteries can be very flexible, but it is difficult for monocrystalline silicon solar cells to achieve this."

In order to make the impossible possible, Liu Wenzhu and his collaborators embarked on a long journey of experimentation.

Silicon solar cells are originally a flat surface with severe light reflection. In order to improve their power generation efficiency, it is necessary to reduce light reflection. A common practice is to place silicon wafers in chemical solvents, and many pyramid-shaped microstructures will appear on the surface. When light comes, it bounces back and forth on these structures, allowing most of the light energy to enter the silicon chip, where it contributes to electricity generation.

"We found that there is a very sharp 'V'-shaped groove at the junction of the pyramid and the pyramid. If a little force is applied to this place, a crack will appear. Starting from here, it may be possible to change the fragile soul of the silicon wafer." Liu Wenzhu said in an interview with "China Science Daily".

The research team did a simple chemical treatment on the silicon wafer, through isotropic chemical etching or plasma treatment, and turned the "V"-shaped groove into a "U"-shaped groove. "This method allows the bending strain to be effectively dispersed, effectively inhibits the strain fracture behavior, and improves the flexibility of the silicon wafer." Di Zengfeng, the corresponding author of the paper and a researcher at the Shanghai Institute of Microsystems, introduced.

But as soon as this end was pressed, the other end was raised again. Although the mechanical properties have been optimized, the reflection has also increased, and the power generation efficiency has been greatly reduced. How to achieve both mechanical properties and power generation efficiency has made everyone very distressed.

The research team intends to find a breakthrough in the full details of the silicon fragmentation. This requires an ultra-high-speed camera that can continuously take 1 million photos per second. Liu Wenzhu sent the samples to Yang Ziqiang, a junior who was also in the fluid mechanics team of King Abdullah University of Science and Technology. Yang Ziqiang used an ultra-high-speed camera to show the entire process of the silicon wafer breaking under bending stress.

"We have seen that the fracture of all silicon wafers under bending stress starts from the edge. This shows that the most edge region is the 'mechanical short board' of the silicon wafer." Liu Wenzhu said, "Then, we only need to deal with the entire large A very small area at the edge of the silicon wafer, and the problem can be solved."

In this regard, the research team innovatively developed edge smoothing technology. They stack dozens, hundreds or more silicon wafers together, and combine the plasma etching method to process the sharp "V"-shaped grooves on the surface and sides of the silicon wafers into a smooth "U". font groove.

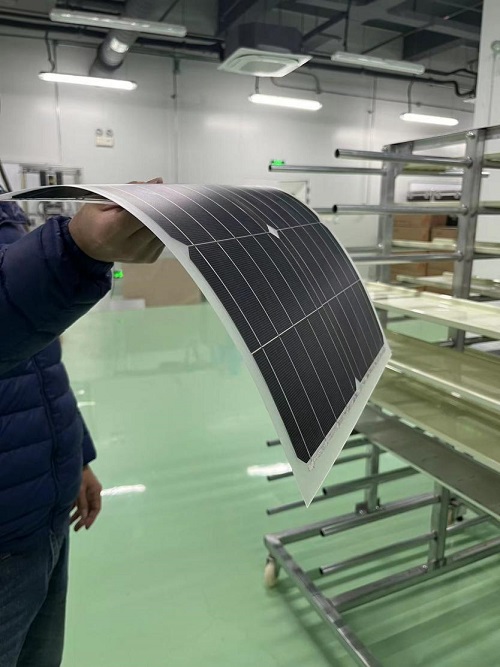

This structural design scheme can significantly improve the "flexibility" of silicon wafers. Monocrystalline silicon solar cells with a thickness of 60 microns can be folded like A4 paper, with a minimum bending radius of less than 5 mm; repeated bending can also be performed, and the bending angle exceeds 360 degrees.

Flexible monocrystalline silicon solar cells are bent over 360 degrees. Photo provided by the interviewee

"Because the smooth strategy is only implemented on the edge of the silicon wafer, it basically does not affect the photoelectric conversion efficiency of the solar cell, and at the same time can significantly improve the flexibility of the solar cell. It has broad application prospects in space applications, green buildings, and portable power supplies in the future." Liu Zhengxin, the corresponding author of the paper and a researcher at the Shanghai Institute of Microsystems, said.

The evidence is sufficient to convince the reviewers

In 1954, researchers at Bell Laboratories in the United States invented monocrystalline silicon solar cells, using monocrystalline silicon wafers to achieve a breakthrough in converting sunlight energy into electrical energy, and successfully used it in artificial satellites.

In the following 69 years, "Nature" has not published a long research paper on monocrystalline silicon solar cells. So when this article was submitted to the journal editors, their eyes lit up, and the article quickly entered the review process.

In the first round of review, one reviewer gave a high evaluation, thinking that "this is a breakthrough discovery in the field of photovoltaics in the future", although the other reviewer did not directly reject the manuscript, but put forward many Details matter.

"Maybe my English writing is not very good. I feel that the second reviewer didn't fully understand the article. Later, I broke it up and explained it to him in response to the questions he raised." Liu Wenzhu said.

During the second round of review, the reviewer wrote that "in any case, the work itself is first-rate and published in Nature is fair."

After the article was submitted, the relevant macromechanical experiments were still in progress. When the article was submitted for review and no feedback was received, the research team made new progress, using the three-point bending method to test the mechanics of monocrystalline silicon solar cells. Performance, and calculate how much its theoretical limit can reach.

When the reviewers did not propose supplementary experiments, they added the research progress obtained in the later period to the article, forming sufficient evidence to convince the reviewers. The article was submitted on August 24, 2022, and was accepted in principle after 5 months. But why is the article not online until now?

"It's all caused by pictures!" Liu Wenzhu said, "I have never submitted to such a good journal before. I just submitted to Nature more than a year ago, but was rejected. I have no experience in making pictures. The pictures are ugly, and after the article notification was accepted, it went through 5 rounds of detailed revisions."

Liu Wenzhu was really surprised to be finally selected as the cover of the current issue. In his opinion, the competition for the cover design of "Nature" is very fierce. "I didn't know painting at the time, and I had no aesthetic awareness. I kept thinking about where the concept of flexibility could be used in the future. When I saw a street lamp on the street, I took a picture of it. Then I curled up the monocrystalline silicon solar cell and stuck it on the lamp post. On the top, do a little hazy effect to highlight the street lights, just two or three simple elements, but the whole picture is simple and clear.”

Leverage the huge flexible photovoltaic market

Whether a technology is reliable requires multi-party verification. The research team not only made monocrystalline silicon solar cells, but also considered many back-end things, and sent the flexible modules of monocrystalline silicon solar cells to third parties for testing.

"There is a company in Jiangsu that specializes in vibration testing of high-speed rail shells. We send the flexible components of about one square meter to the test. We fix the components around the base plate and leave the middle in the air. After the vibration test starts, the components will be like mats. Shaking up and down." Liu Wenzhu said.

Under such a harsh test environment, they measured 18,000 cycles, and the power of the flexible component was not damaged at all.

In addition to this test, the research team also made more "ruthless" operations. The international standard for photovoltaics is the IEC standard, which means that photovoltaic materials must be able to operate for 20 or 25 years between minus 40°C and 85°C, and the performance degradation should not exceed 15%.

"The experiment we did was more stringent than the international standard. We let the monocrystalline silicon solar cell cycle continuously for 120 hours between minus 70°C and 85°C, and found that the power attenuation was very small." Liu Wenzhu introduced.

That's the good side of silicon, it's very stable. Liu Wenzhu said that although the multimode battery is very thin and flexible, it has a polycrystalline structure. Under a microscopic microscope, it is made up of grains, which means that there is a grain boundary between each grain and the adjacent grains. If you bend and fold it back and forth, the grain boundaries will The formation of mechanical friction leads to performance attenuation.

"Now, we have made a flexible monocrystalline silicon solar cell. The entire large silicon wafer can be restored to its original shape no matter how it is bent. It has no grain boundaries and no friction. Even if it is folded 1,000 times, the power will not attenuate at all, and the service life will be very long. .And these are difficult to achieve with polycrystalline cells.” Liu Wenzhu said.

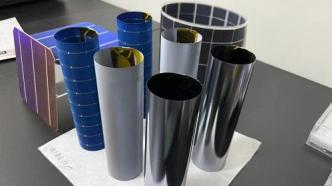

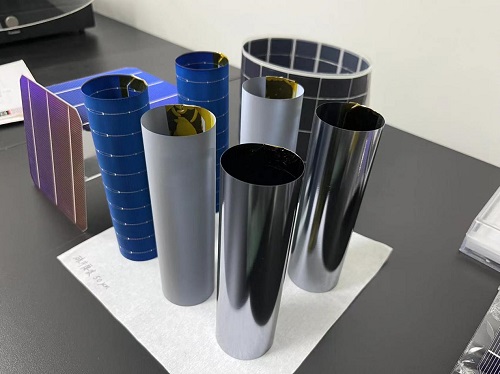

Client-oriented products. Photo provided by the interviewee

Flexible monocrystalline silicon solar cell modules have been successfully applied in the fields of near-space vehicles, building-integrated photovoltaics, and vehicle-mounted photovoltaics. Photo provided by Shanghai Microsystems Institute

This study verified the feasibility of mass production in the mass production line, and provided a feasible technical route for the development of lightweight and flexible monocrystalline silicon solar cells. The large-area flexible photovoltaic modules developed by the research team have been successfully applied in the fields of near space vehicles, building photovoltaic integration and vehicle photovoltaics.

Liu Wenzhu said that flexible monocrystalline silicon solar cells will be used in more scenarios in the future, such as street lamps, wearable electronics, mobile communications, aerospace and other fields, which have good development space, or can leverage the huge flexible photovoltaic market.

Related paper information: https://doi.org/10.1038/s41586-023-05921-z