Prepared ferroelectric polymers with both ferroelectricity and flexibility.

In recent years, people's consumption of flexible wearable devices is increasing. As one of the important raw materials, the elasticity of ferroelectric materials with a history of one hundred years is imminent, but the research and development process is very difficult. Because the source of ferroelectricity of this material is crystal, it has almost no elasticity, low elongation rate, and no rebound ability.

How to combine ferroelectricity and elasticity to make wearable devices softer and more elastic?

In response to this problem, researchers Hu Benlin and Li Runwei of the Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences finally made a breakthrough through scientific research, increasing the elastic recovery of the aforementioned materials below 5% to 125% , opening up a new "elasticity" Ferroelectric" subject direction.

On August 4, their research paper was published online in the international academic journal Science. The title of the paper is "Intrinsically elastic polymer ferroelectric by precise slight crosslinking".

On the 3rd, Hu Benlin told The Paper that ferroelectric materials are multifunctional materials that are difficult to replace in certain specific applications. For example, high-capacity capacitors can be made of ordinary materials, but the energy density is low; another example is transducers (sonar, piezoelectric nozzles, ultrasonic imaging, etc.), ferroelectric ceramics must be used.

Regarding the difference between flexible materials and elastic materials, Hu Benlin introduced that it is mainly in the strain range, "flexibility is generally less than 5%, and can only be bent; while the strain range of elasticity is much greater than 5%, and can be stretched repeatedly, of course, bending is also possible." .

Ferroelectric materials have numerous applications in data storage and processing, sensing and energy conversion, and nonlinear optical and optoelectronic devices. It is used in electronic products such as computer memory, high-precision motors, ultra-sensitive sensors and sonar equipment, and is also one of the essential materials in electronic devices such as mobile phones and tablet computers.

Sensors made of elastic ferroelectric materials are more "easy-going", have higher measurement accuracy, and better wearing comfort, bringing broad imagination space for smart medical, smart wearable and other fields.

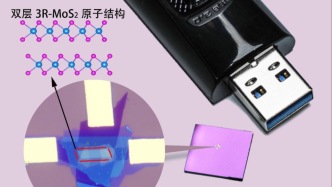

Schematic illustration of the concept and synthetic strategy of elastic ferroelectrics.

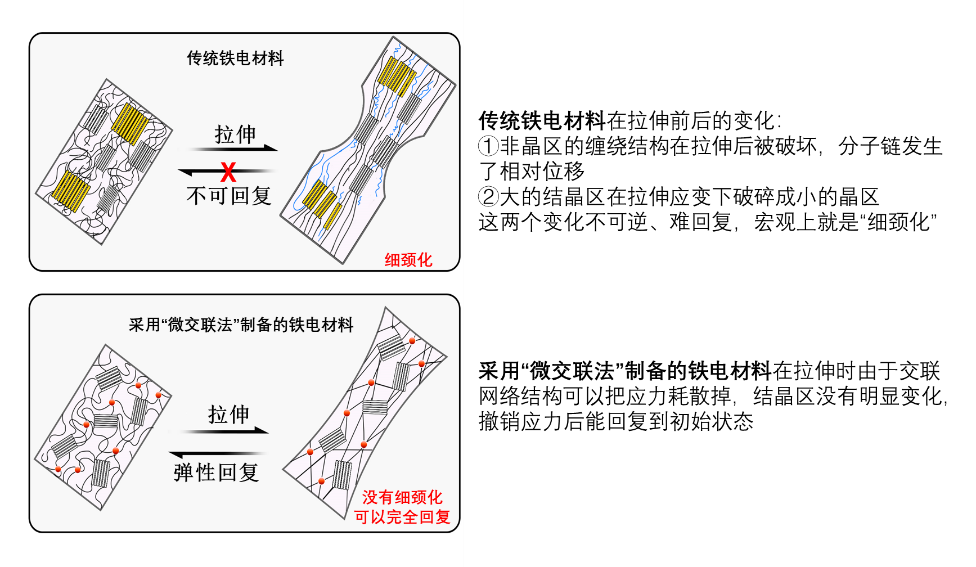

The research team used the "micro-crosslinking method" to put wings on the ferroelectric material. By precisely controlling the amount of cross-linking agent, a small amount of soft chain-like polymers interweave to form an elastic fishnet-like structure, which loosely connects the ferroelectric crystals together, and produces reversible deformation when the external force acts, avoiding damage to the crystallization Part of the damage is caused, so that the material can still maintain stable ferroelectricity within a certain stretching range.

This elastic ferroelectric material not only has good tensile resilience, but also has excellent tensile stability, can withstand thousands of repeated stretches, improves reliability and service life, and expands the scope of use.

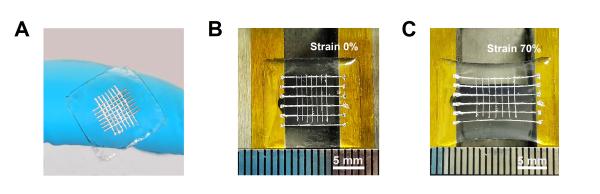

Elastic ferroelectric materials under strain.

Journal reviewers commented that the work employs an unusual and striking design strategy. In the 100-year history after the discovery of ferroelectric materials, compared with the original tensile strain of ferroelectric ceramics of no more than 0.2%, and the original elastic recovery of polymer ferroelectric materials of less than 2%, this is a breakthrough work.

Paper link: https://www.science.org/doi/10.1126/science.adh2509